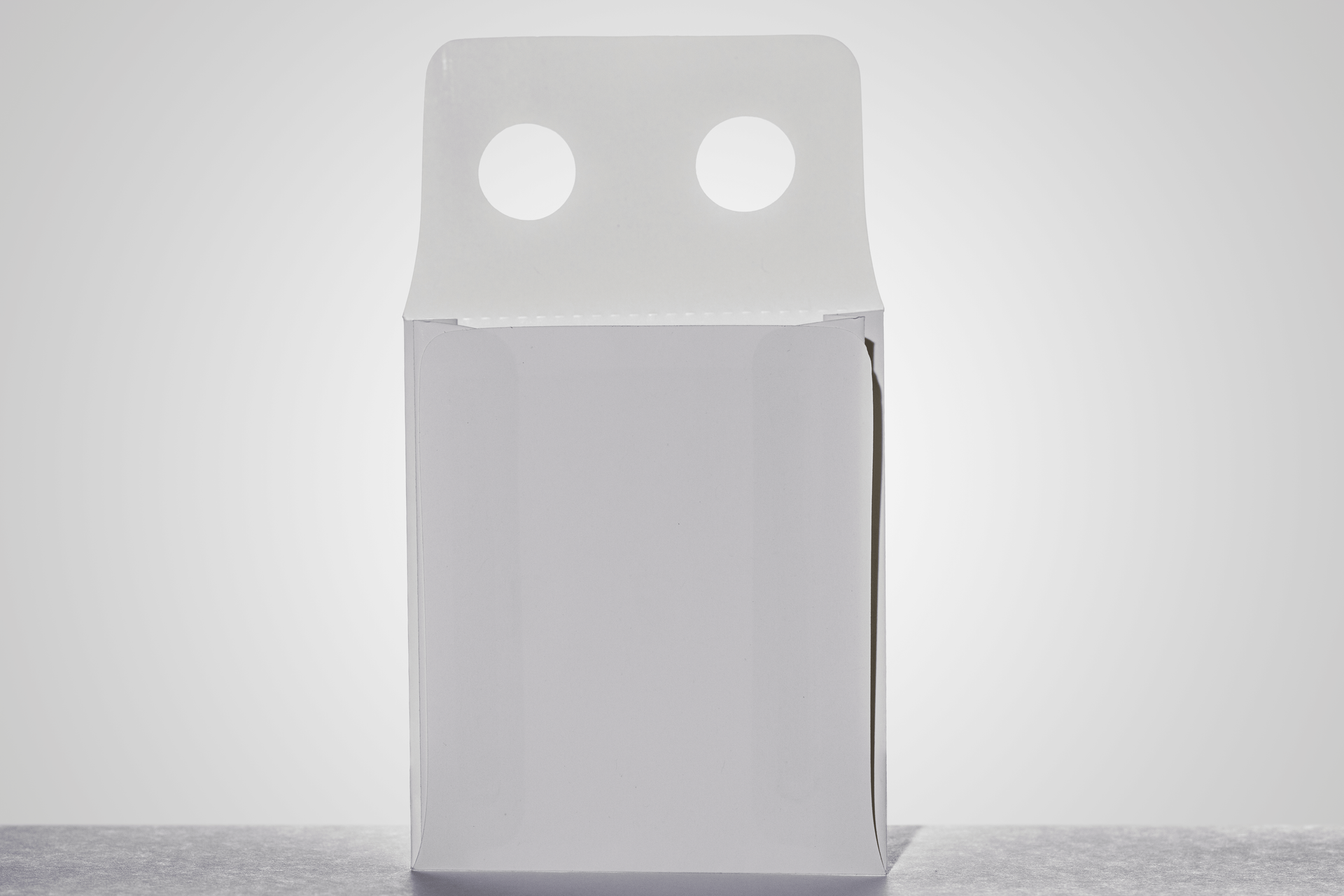

Blank Finished Single Vision (FSV) Envelope (Expandable)

Description:

Available in two versatile sizes, 82mm by 92mm and 90mm by 90mm, our Expandable Blank Finished Single Vision (FSV) Envelopes are expertly crafted from premium-grade 80# white matte paper. These envelopes are also available with holes in the top closure flap as shown. When a label is placed over the holes and the flap is closed, the label adhesive will then hold the flap securely closed. Engineered with accuracy, these envelopes are compatible with automated robotic packaging systems, streamlining your workflow. Inside, the envelopes feature an interior lining made of optical-grade non-woven fabrics, cradling the lenses gently and safeguarding them from scratches or damage.

Shipping and Turnaround Times: If the item is in stock, then it ships the same day or the next day. If it is a standard custom order item, then you can expect it to be shipped about 10 days after proof approval. If it is a special custom order, then shipping will take 3-4 weeks.

Materials Used: Lined with protective, non-woven fabrics that are designed not to scratch or leave any particulates on the lenses.

Sizing and Dimensions

Product Sizing Specifications

Closed

Open

Unfolded

Frequently Asked Questions

Commonly Asked Questions & Helpful Responses

-

What type of paper do you use to create your Blank Finished Single Vision (FSV) Envelope (Expandable)?

This expandable envelope is produced from 80# premium-grade white matte paper.

-

What sizes do the Blank Finished Single Vision (FSV) Envelope (Expandable) come in?

These envelopes come in the following sizes:

- 82mm by 92mm

- 90mm by 90mm

-

What are the Blank Finished Single Vision (FSV) Envelope (Expandable) best used for?

These envelopes are best used for protecting lenses for your clients.

-

What are the interior of the envelopes lined with?

The interior of the envelopes are lined with optical grade non-woven fabrics.

-

How should I send my custom envelope artwork?

Attached is a general guide for layouts. It is HIGHLY advisable to print, cut, and fold layouts to check for proper bleeds, spacing away from folds and die line edges, and to insure no art is being covered by areas that fold over each other.

Also, the attached .ai Template has TWO layers: Layer 1 is the die line. This should ALWAYS remain the exact color it is, remain ‘locked’, and kept isolated from the ‘Art’ layer. The second layer is for the graphics to be printed, and should contain ONLY the graphics to be printed. Any extraneous objects or duplicate objects should be removed from the file.

Here’s some suggestions that will have them print far better, easier, sharper, and dry quicker:

1) All black text and background should be on the Key[K]/Black separation ONLY.

2) All logos would reproduce better in vector format; if not available, should be 400ppi/dpi

3) All images should be 400ppi/dpi.

4) All text should be vector.

5 All colored text should be just that… text ‘filled’ with the appropriate color, NOT a text mask with a colored block behind it[as Photoshop files tend to do].

6) All front/back/bottom/side bleeds should be a minimum of 1/16th of an inch.*

7) All text and images should be a minimum of 1/16th of an inch away from folds and die cutting areas.*

8) Full coverage bleeds beyond the die cut should be a minimum of ¼ of an inch.

9) All spot color[PMS Colors] must be converted to process color[CMYK].

10) Files should be submitted in .pdf format.

*1/16th inch is the MINIMUM. We encouraged using 1/8th - 3/16th inch for internal bleed areas[over folds], as well as spacing elements away from folds and cutting areas.

What Happens After I Send My Message?

Our team will review your information.

A staff member will contact you as soon as possible.

We will work with you to order your products.

Request A Quote

For more information or to schedule a service, call us at (860) 963-1231 or complete the form.

Contact Us

We will get back to you as soon as possible.

Please try again later.

Our Contact Information

Request a Quote From Creative Envelope!

Business Hours

- Mon - Fri

- -

- Sat - Sun

- Closed